- Agent Brand

- KIMAX Product

-

Energy Saving Product

- PM direct drive motor(PMDDM)

- CT Water Turbine(CTWT)

- Permanent Magnet Coupling(PMC)

- High-efficiency pumps & Plastic pumps(3D impeller)

- Hydraulic recovery Turbine Power Generation system(HTPG)

- WWS PowerGate Water Turbine - (Taiwan General Agent)

- Maglev Oil-free Centrifugal Chillers

- Maglev Oil-free Centrifugal Air Compressor

- High Eff Turbo Blower (Air Bearing)

- Pressure Letdown Energy Recovery(Steam)

- Microgrid Wind and Solar Energy

High-efficiency pumps(3D blades) & Plastic pumps

High-efficiency pumps(3D blades)

1. Customized design and production can be made according to customer needs.

2. Meet Ashrae 90.1's energy-saving indicators for air-conditioning water-side systems.

3. Can reach the EU minimum energy efficiency standard from C40~C80.

4. The 3D impeller is customized by a five-axis processing machine.

High-power plastic pump

1. Maximum power: 132KW

2. Effectively replace the special alloy pump required for special process fluids.

3. Suitable for pumps with acidic or alkaline fluids.

4. One-piece thermoplastic process to ensure zero leakage.

Efficient impeller design.

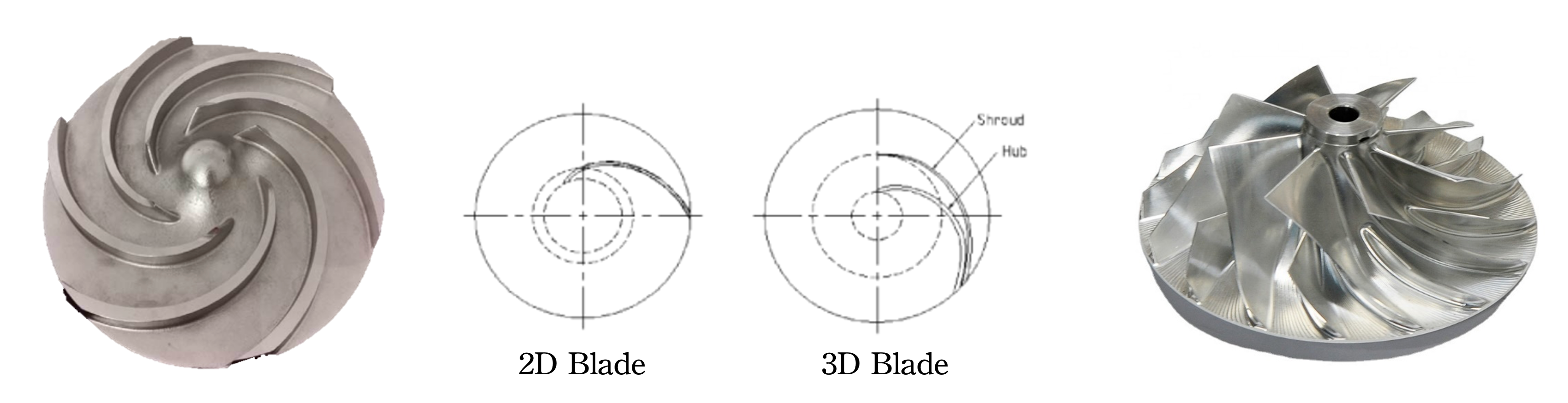

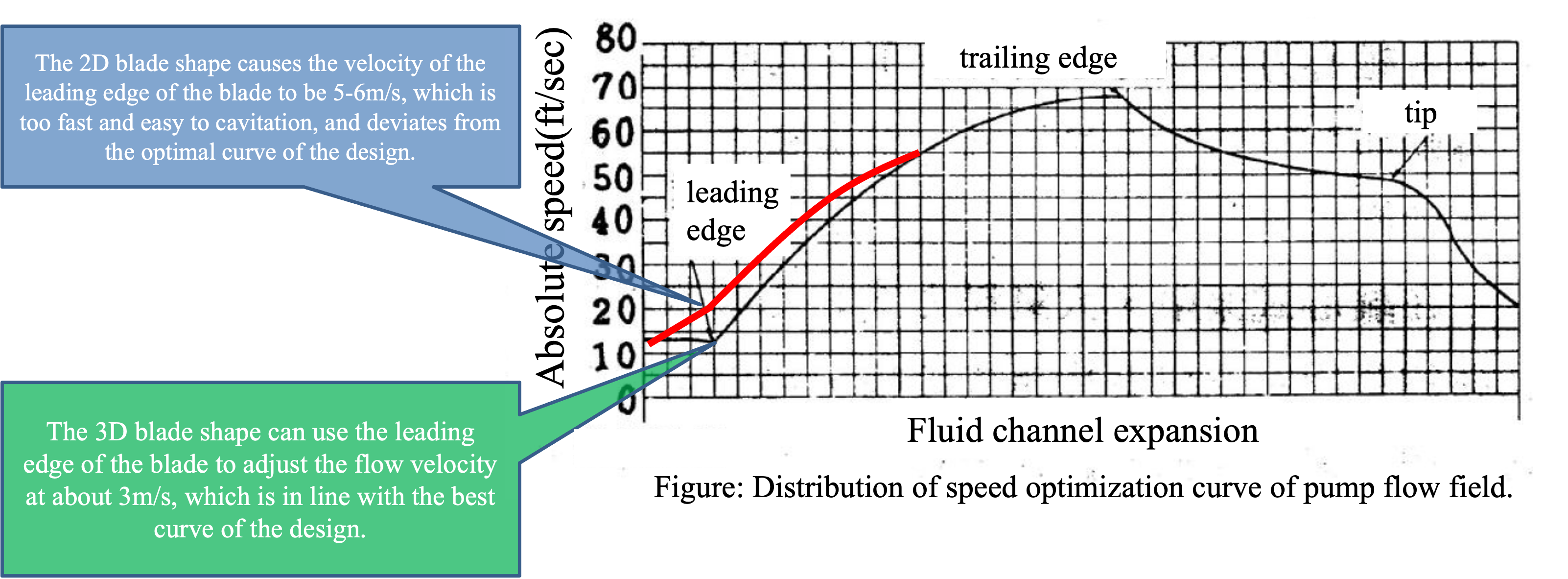

The difference between 2D & 3D impellers.

The efficiency curve of the water pump is mainly designed and manufactured according to the optimized curve of the velocity distribution of the flow field. If a 2D impeller is used, the appearance of the blade is molded into a two-dimensional plane with a simple machine, so the pump cannot be close to the best curve of the flow field velocity distribution during actual operation, so the efficiency is poor. The blades of the 3D impeller are moulded and manufactured using a 5-axis processing machine, so that the blades have curved surfaces and angles as three-dimensional, so that the pump matches the optimal curve of the flow field velocity distribution during actual operation, with high efficiency and can meet the requirements of C40~C60 Energy efficiency standards, if energy efficiency certification is required, it can be sent to a third-party unit for confirmation.